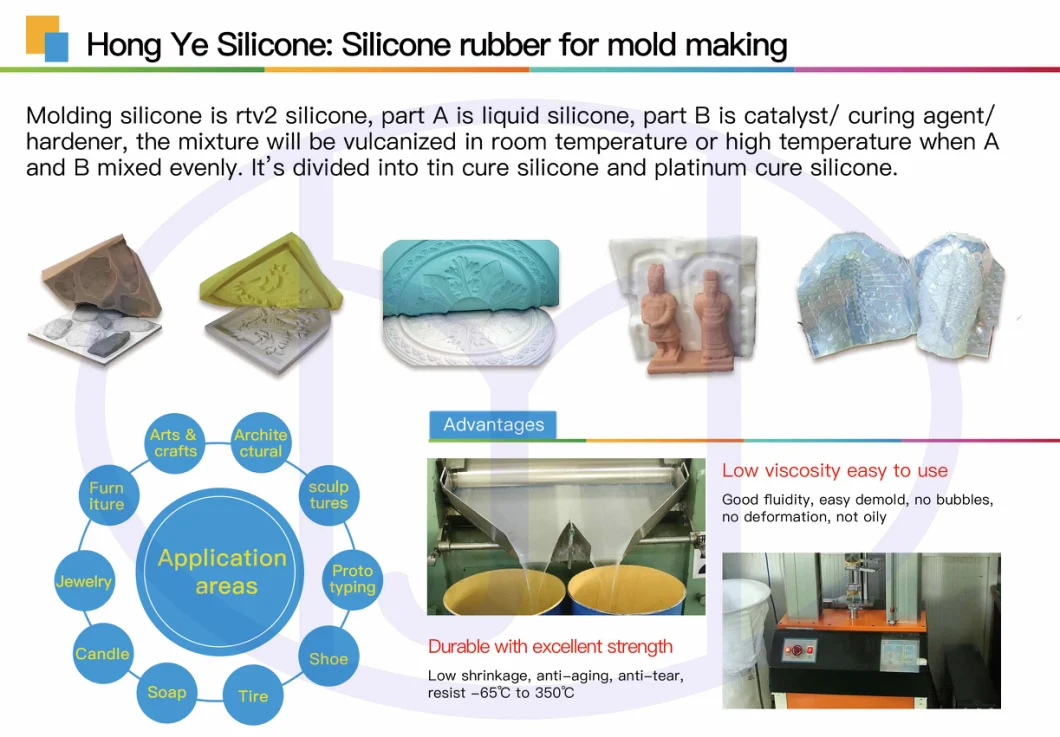

Mold making silicone rubber provided by Hong Ye Silicone is two component silicone, also called rtv2 silicone, which will be vulcanized in room temperature when mix part A and part B evenly.Hong Ye provides food grade silicone rubber, belongs to platinum cure silicone and addition cure silicone, the general mix ratio of A and B is 1:1 or 10:1.

Molding silicone is suitable for reproducing and replicating variety of products in large quantity, such us art crafts, furniture, prototyping, architectural elements, garden ornaments, shoe, tire, soap, candle, jewelry, vacuum bag and so on. Molds silicone rubber is also suitable for making molds for variety of material, such as resin, PU, PVC, polyester, gypsum, plaster, concrete, cement, stone, GRC, wax, jewelry and so on.

1)Flexible and low viscosity which will copy finest details and patterns from exquisite products.

2)Durable with good strength, top quality to guarantee molding times

3)Easily demolding

4)Not oily, no bubbles

5)Can resist high temperature 200ºC - 350ºC, and low temperature -65ºC

6)Low shrinkage less than 0.2%, platinum cure type is less than 0.1%

7)Aging resistance, acid and alkali resistance

8)Platinum cure silicone is FDA certificated, nontoxic, odorless

| Model | Color | Mixing ratio (%) | Pot life (mins, under 25ºC) | Curing time (hrs,under 25ºC ) | Hardness ( Shore A ) | Tensile- strength (MPa) | Tear- strength (kN/m) | Viscosity (After A/B mixed ,mPa.s) | Shrinkage rate (%) | Elongation (%) |

| HY-605 | White | 2-3 | 30-40 | 4-5 | 5±2 | 1.5+1/-0.3 | 7+4/-2 | 5000+500/-500 | ≤0.3% | 330% |

| HY-610 | White | 2-3 | 30-40 | 4-5 | 10±2 | 1.6+1/-0.3 | 8+4/-2 | 10000+2000/-4000 | ≤0.3% | 320% |

| HY-615 | White | 2-3 | 30-40 | 4-5 | 15±2 | 2.5+1/-0.3 | 16+4/-2 | 13000+2000/-4000 | ≤0.3% | 350% |

| HY-620 | White | 2-3 | 30-40 | 4-5 | 20±2 | 3.0+1/-0.3 | 19+4/-2 | 17000+2000/-4000 | ≤0.3% | 400% |

| HY-625 | White | 2-3 | 30-40 | 4-5 | 25±2 | 3.8+1/-0.5 | 24+5/-2 | 25000+5000/-8000 | ≤0.3% | 400% |

| HY-630 | White | 2-3 | 30-40 | 4-5 | 30±2 | 4.3+1/-0.5 | 26+5/-2 | 27000+5000/-8000 | ≤0.3% | 400% |

| HY-635 | White | 2-3 | 30-40 | 4-5 | 35±2 | 4.3+1/-0.5 | 24+5/-2 | 27000+5000/-8000 | ≤0.3% | 200% |

| HY-640 | White | 2-3 | 30-40 | 4-5 | 36±2 | 3.5+1/-0.3 | 17+5/-2 | 15000+2000/-5000 | ≤0.3% | 150% |

Shenzhen Hong Ye Jie Technology Co., Ltd. is a science and technology corporation established in 1998, engaged in research and development, production, sales of silicone rubber with the brand Hong Ye Silicone, abbreviated as HY Silicone.Hong Ye Silicone produces rtv-2 silicone rubber, includes platinum cure silicone rubber and tin cure silicone rubber.As for the stars products, it includes Mold Making Silicone, Electronic Potting Silicone, Skin Safe Silicone, Pad Printing Silicone, Medical Grade Silicone, Liquid Silicone Foam, Silicone Gel, Life Casting Silicone, Textile Coating Silicone, Injection Silicone and so on.

SHENZHEN HONG YE JIE TECHONOLOGY CO., LTD.

ADDRESS: Building A, No.3, Hongling First Road, Liulian Shibi, Pingdi Street, Longgang, Shenzhen, Guangdong, China

Zip code: 518117

Website: http://wendy-rl.en.made-in-china.com

E-Catalogue: http://le-marketeur.com/Silicone-Rubber/E-Catalogue2013.swf